Lembaran Tembaga

Pengenalan Produk

Lembaran Loyang berasaskan kuprum elektrolitik, zink dan unsur surih sebagai bahan mentahnya, melalui pemprosesan jongkong, penggelek panas, penggelek sejuk, rawatan haba, pembersihan permukaan, pemotongan, kemasan, dan kemudian pembungkusan. Prestasi proses bahan, keplastikan, sifat mekanikal, rintangan kakisan, prestasi dan timah yang baik. Ia telah digunakan secara meluas dalam industri elektrik, automotif, komunikasi, perkakasan, hiasan dan lain-lain.

Parameter Teknikal Utama

2-1Komposisi Kimia

| Nama | Aloi No. | Komposisi Kimia (%, Maks.) | ||||||||

| Cu | Fe | Pb | Al | Mn | Sn | Ni | Zn | Kekotoran | ||

| Tembaga | H96 | 95.0-97.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 |

| H90 | 88.0-91.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H85 | 84.0-86.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H70 | 68.5-71.5 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H68 | 67.0-70.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H65 | 63.5-68.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H63 | 62.0-65.0 | 0.15 | 0.08 | --- | --- | --- | 0.5 | Rem | 0.5 | |

| H62 | 60.5-63.5 | 0.15 | 0.08 | --- | --- | --- | 0.5 | Rem | 0.5 | |

Meja Aloi 2-2

| Nama | China | ISO | ASTM | JIS |

| Tembaga | H96 | CuZn5 | C21000 | C2100 |

| H90 | CuZn10 | C22000 | C2200 | |

| H85 | CuZn15 | C23000 | C2300 | |

| H70 | CuZn30 | C26000 | C2600 | |

| H68 | --- | --- | --- | |

| H65 | CuZn35 | C27000 | C2700 | |

| H63 | CuZn37 | C27200 | C2720 | |

| H62 | CuZn40 | C28000 | C2800 |

2-3 Ciri

2-3-1Unit Spesifikasi: mm

| Nama | No. Aloi (China) | Perangai | Saiz(mm) | ||

| Ketebalan | Lebar | Panjang | |||

| Tembaga | H59 H62 H63 H65 H68 H70 | R | 4~8 | 600~1000 | ≤3000 |

| H62 H65 H68 | Y Y2 | 0.2~0.49 | 600 | 1000~2000 | |

| 0.5~3.0 | 600~1000 | 1000~3000 | |||

Tanda Temperatur: O. Lembut; 1/4H. 1/4 Keras; 1/2H. 1/2 Keras; H. Keras; EH. Ultra keras; R. Digulung Panas.

Unit Toleransi 2-3-2: mm

| Ketebalan | Lebar | |||||

| Ketebalan Benarkan Penyimpangan ± | Lebar Benarkan Penyimpangan ± | |||||

| <400 | <600 | <1000 | <400 | <600 | <1000 | |

| 0.5~0.8 | 0.035 | 0.050 | 0.080 | 0.3 | 0.3 | 1.5 |

| 0.8~1.2 | 0.040 | 0.060 | 0.090 | 0.3 | 0.5 | 1.5 |

| 1.2~2.0 | 0.050 | 0.080 | 0.100 | 0.3 | 0.5 | 2.5 |

| 2.0~3.2 | 0.060 | 0.100 | 0.120 | 0.5 | 0.5 | 2.5 |

| Perangai | Kekuatan Tegangan N/mm2 | Pemanjangan ≥% | Kekerasan HV | |

| M | (O) | ≥290 | 35 | --- |

| Y4 | (1/4J) | 325-410 | 30 | 75-125 |

| Y2 | (1/2J) | 340-470 | 20 | 85-145 |

| Y | (H) | 390-630 | 10 | 105-175 |

| T | (EH) | ≥490 | 2.5 | ≥145 |

| R | --- | --- | --- | |

Tanda Suhu:M. Lembut;Y4. 1/4 Keras;Y2. Keras;Y. Keras;T. Sangat keras.

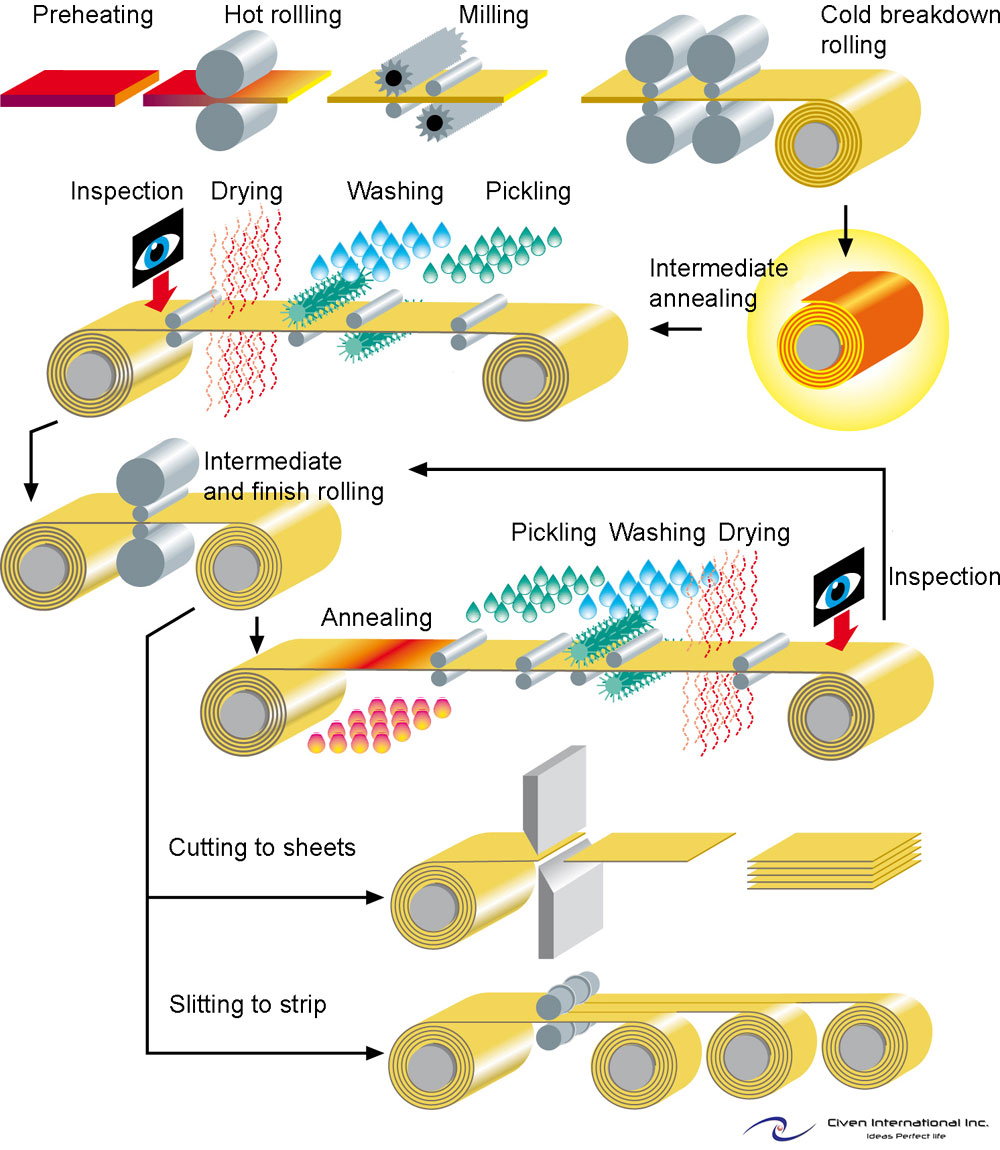

Teknik Pembuatan